Expertise

Preserving manufacturing traditions & knowledge of the past masters.

Our highly skilled team has the experience and expertise required to produce the finest quality silverware, from cutlery, flatware and holloware, to trophies, tableware and bespoke items. Unlike many other companies in our market, we benefit from having all the required skills to make the most exquisite silverware under one roof. This reassures our clients that we are truly the centre of excellence in silverware.

Cutlery and flatware

At British Silverware, we have a huge collection of cutlery and flatware patterns available to our clients. Designs range from well-known English Parish patterns to an extensive catalogue of private patterns and hand-forged designs. Historic tooling and dies from Roberts and Belk, CJ Vander, Cooper Brothers, William Hutton and James Dixon & Sons complete our collection.

Our cutlery and flatware is primarily made by hand, and each piece is exquisitely detailed with superb definition. Find out more in our dedicated cutlery and flatware section.

Design

The Design Department is an integral part of the company and is where the production process most often begins. Our talented designers listen to our clients’ requirements, interpreting the brief and turning their vision into reality. Using CAM technology, we can quickly turn the initial design into a working prototype.

Press shop

All our cutlery and flatware is stamped in our Press Shop and once it has been blanked out, it goes to our Hand Filing department to be hand-finished with the utmost care and attention to detail.

Holloware stamping

Many of our discerning clients choose to complement their cutlery and flatware with a set of matching tableware. In the Stamp Shop, we create a huge variety of products from tea pots to trays and candlesticks to hip flasks. We can produce these in many different shapes and sizes, enabling our clients to offer a range of styles.

Our tableware can be further enhanced by our in-house wire-drawing service, adding standard or bespoke wire patterns to your items. We also manufacture salvers and waiters for the trade, some of which have been used in the most prestigious sporting presentations.

Spinning

Our in-house spinning department has a huge selection of shapes and sizes in our generic tooling. We have tooling chucks for special commissions and we can even make bespoke tooling for our clients. Our spinner is capable of doing wood-turning, which is useful in the production of trophies.

Silversmithing department

Our silversmiths are the lifeblood of the holloware and bespoke department, and it is their finesse that enables us to create unique pieces of silverware together with high quality tableware. They combine years of experience with considerable in-depth knowledge and enthusiasm for their trade.

Our talented silversmiths can turn their talents to the production of almost any item, to suit the myriad requirements of our diverse, worldwide client base.

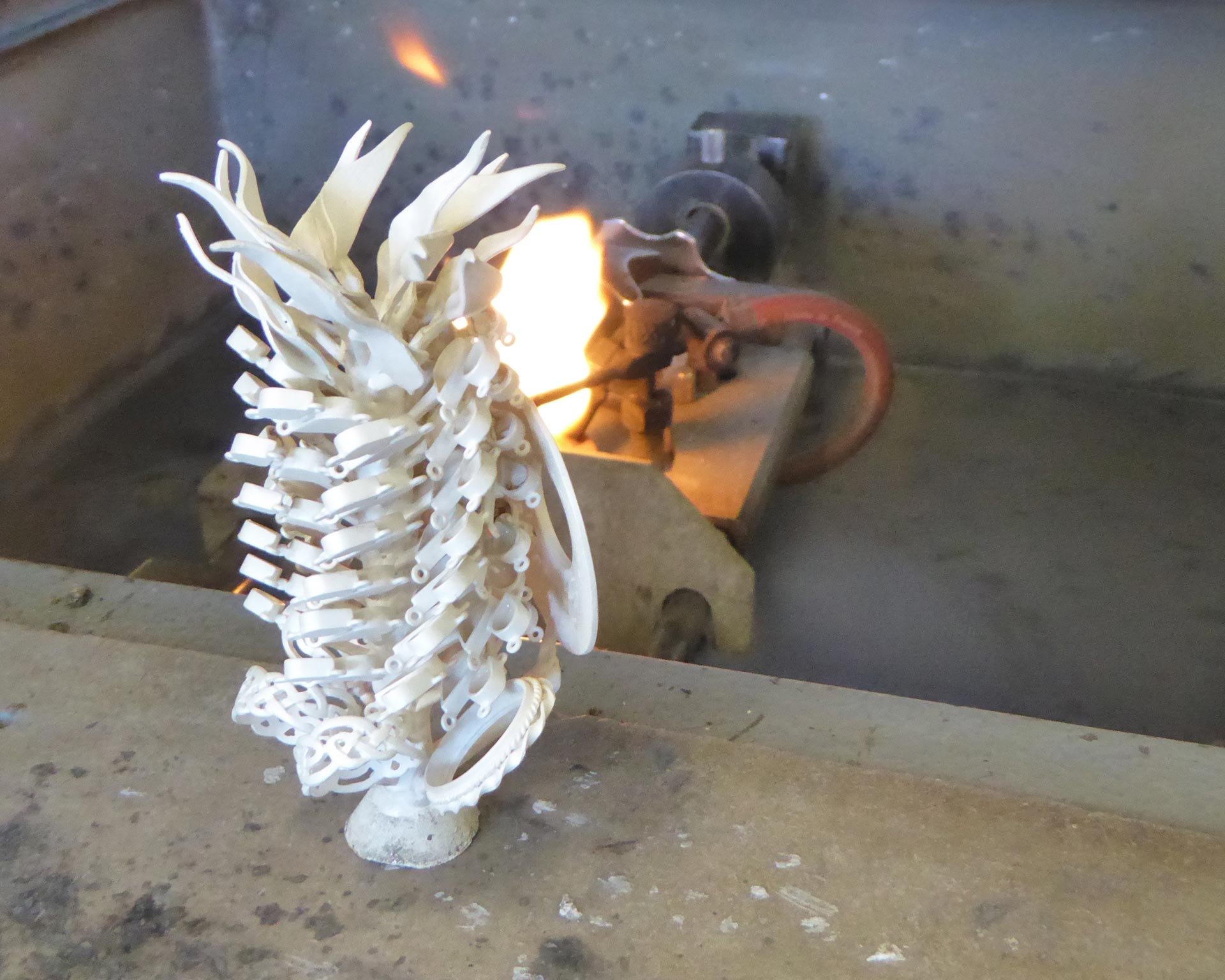

Casting

Our in-house casting department is open to the general trade and we work closely with jewellers throughout the UK and beyond. We have also produced bespoke pieces for the vintage car market, presentation sword parts and many other unique requests.

We offer a full service, from hot and cold mould making, through to waxing and casting. We cast a minimum of twice a week, ensuring a speedy service.

Having our own in-house casting facility also gives us the versatility and flexibility to cast for our own production, from models of animals and ornate door knockers to decorative centrepieces and bespoke jug handles.

Sand buffing

We believe we are one of the last silverware manufacturers to retain the practice of sand buffing. Many companies removed this process in the last century as a cost-cutting measure. However, our commitment to quality means that we refrain from cutting any corners in our production processes.

Our buffing department uses a carefully selected mix of finely ground pumice stone combined with high quality oil. This results in the most beautiful finish on our silverware.

Hand raising and flat hammering

The specialist skills of hand raising and flat hammering are vital to the production process in two distinct ways.

-

Hand raising is the art of taking a flat sheet of metal and fashioning it into any shape using only hammers on stakes. Our team can create truly unique pieces without compromise and restriction. We are also able to replicate a treasured item, replace or add to a collection exactly as required.

-

Flat hammering, also known as bottom hammering, is essential when working on salvers and flat surface pieces, to ensure that heat hasn’t warped the base.

Hand chasing and saw piercing

At British Silverware, we benefit from having one of the few chasing and saw piercing specialists in the UK, enabling us to offer our clients a true, artisanal craft.

This intricate and artistic process is used when our clients require bespoke decorations to be added to their silverware. The decoration, which can be designed by the client, is transferred by hand on to a single trophy, or a one-off set of private tableware. We also offer hand piercing to create unique centre pieces. This process is perfectly suited to one-off items or small, bespoke production runs, which would not allow for costly tooling.

Jackie Tear - Managing Director

"We have created a hand chasing apprenticeship programme to ensure that this distinctive silverware skill continues to thrive in the 21st century and beyond.”

Silver polishing

Our products undergo a number of specialist finishing processes. After being prepared in the Buffing Shop, each item goes on to the Polishing Department, where it will be polished by hand, on spindles. Polishing each piece by hand gives the best possible finish, whilst ensuring the pattern definition is fully retained. We use a variety of compounds and high-grade polishing mops to achieve the beautiful finish that our products are so well known for.

Electroplating

Having all elements of the production process under one roof enables us to fully control the quality of our products.

Having our own Silver Plating and Gold Plating departments is the perfect example of how this works in practice. We are able to use our XFR machines to measure the quality of the precious metals we use, giving our clients reassurance that the required deposits have been achieved. It also gives an accurate timeline for the creation of the silverware.